Boat Maintenance- How to care for your boat

The Peace of Mind Approach

Boat maintenance doesn’t have to be all time-consuming, but a well-planned programme is always the best approach for retaining your boat’s value and ensuring reliability.

It’s best not to simply wait for niggles to appear, this is likely to result in unexpected repair bills, with boat maintenance preservation is key.

Whatever the vessel, it’s worthwhile employing a continuous process to keep an eye on anything that may need attention, particularly engines, systems, fittings, chafe in ropes, sail damage, and so on.

Adopt a ‘peace of mind’ approach, look for the first sign of any problem and then monitor wear over time, knowing you are keeping an eye on things will help free you of worry and anxiety and ensure you know the condition of your boat well when things do start to go wrong.

Protect your investment and minimise expenditure by staying on top of your boat maintenance.

The old saying that ‘a stitch in time saves nine’ is just as appropriate for today’s yachts and motorboats as when the ships sailed across the oceans carrying the world’s trade. Pay particular attention to the mechanical and electrical systems and anything that may allow water to penetrate into the structure of the vessel, such as leaky deck fittings.

Keep the boat clean. As well as making it more inviting for yourself and guests, this will help to keep damp and mould away – both inside and outside.

Seasonal Considerations

For most owners there are also seasonal aspects to maintenance. Winter is often considered to be ‘maintenance season’, where the whole boat is checked over and the bottom re antifouled to reduce growth of marine organisms during the summer.

If done correctly, the laying up process will highlight most of the tasks that need to be completed by the start of the following season. Although most boats are kept afloat, and often fully in commission, through the winter it’s still good practice to identify and list any potential problems at the end of the main boating season.

If contractors such as marine engineers or sailmakers need to be engaged to fix any of these it’s much better to instruct them in October or November, rather than in April, when they are likely to already be at full stretch.

A planned maintenance schedule will produce better results than an ad-hoc approach.

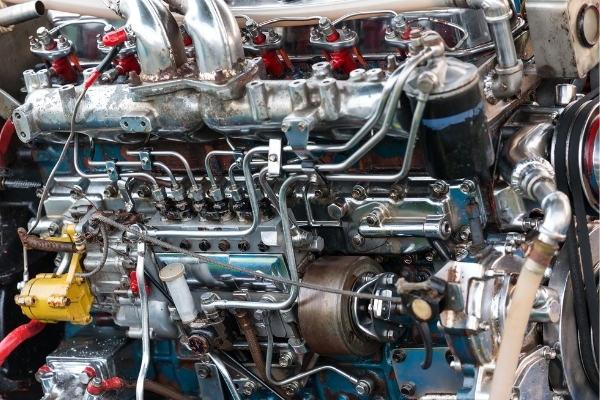

Engine Care

Diesel inboard engines require an annual service including changing oil, oil filter and fuel filters. Ideally this should be carried out before the winter lay up and the engine winterised at the same time. Daily checks include drive belt tension and condition, an examination of all wiring and pipe work to check for loose connections and chafe, and sump oil level and coolant level in the heat exchanger of fresh-water cooled units.

Ignoring engine maintenance stores up problems for later.

Protecting your boat from corrosion is essential. Sacrificial anodes should be replaced when they are approximately one-third degraded (which in practice often means annually). It is advisable to examine the outer edges of the propeller blades for damage. Surface pitting, accompanied by a pink-toned discolouration, is a sign of electrolytic action and should be investigated further. Also, check the cutless bearing in the P bracket for wear – it should be snug fit around the shaft.

Damage to metal through-hull fittings is often caused by the process of electrolysis. A white powder inside the hull around the fitting is a sign of dezincification, requiring replacement of the fitting. In any case, check all seacocks operate freely, and grease them before launching. Also, check log and depth-sounder transducers for damage. Bilge pumps (and heads pumps) need periodic servicing. This may not be necessary annually if they are only used occasionally, but should certainly be carried out every other year.

Fibreglass Maintenance

A regular polish and wax will help to keep fibreglass looking like new and is especially important for deep colours, which have a tendancy to fade relatively quickly. Large areas on badly faded topsides are best dealt with using an electric polisher.

A periodic check of fibreglass mouldings for scratches, chips, stress cracks and other gel coat damage is important. Any cracks should be investigated to see how deep they penetrate, using a sharp chisel to open the crack into a v shape – if it does not extend beyond the gelcoat, a cosmetic repair of the gel is all that is required. However, if damage extends into the laminate below then a professional repair will be needed.

When doing regular tasks – like stripping, repainting and antifouling, you have an ideal opportunity to check for problems.

Care for your Timber

Teak decks on fibreglass or metal boats have a certain lifespan and replacement can be expensive – any signs of loose caulking, split planks or leaky deck fittings should be attended to straight away to prevent water from getting under the deck. Much of the damage to such decks is the result of scrubbing with a stiff brush, which can wear up to 1mm per year from the timber. A soft brush, used gently across the grain when washing decks will avoid this wear, with the timber gradually acquiring a natural silvery appearance.

Wooden boats are at risk of damage caused by failure of the paint, varnish or epoxy coatings and the ravages of freshwater and frost. Salt water, on the other hand, is a mild preservative, so most problems are found where rainwater is allowed to settle, with any damage in the protective coatings enabling rot to take hold.

Poor ventilation is the other key threat to wooden structures. Dinghy covers should be made of a breathable material and yachts need a good air flow through the accommodation areas and locker spaces, unless they are equipped with a marine specification dehumidifier. This should be a priority on any boat, to prevent it becoming stale, damp and mouldy. The difference with a fibreglass vessel is simply that the structure won’t deteriorate, although soft furnishings and anything stored on board will certainly suffer if the interior is left to become damp.

Safety First

Always look after your safety kit – it’s vital you have the appropriate gear on board – and is an on-going part of boat maintenance. Flexible gas pipes tend to last around 5 years, but if they show any signs of perishing, or if braided outer cores are starting to fray, they should be replaced immediately by a qualified marine fitter. All safety gear should be given a thorough check and service each year with lifejackets examined more frequently for chafe or damage to the stitching, and to confirm that the inflation bottle is firmly screwed in place.

Sails and Rigging

Examine sails for damage to stitching, as well as nicks, chafe and tears in the fabric – when sailing the smallest damage will show clearly against the sun. Focus carefully on high load zones, batten pockets and the leech of headsails.

Check the rig at least once a season. A full rig check is a sensible precaution at least once a year. A visual check won’t tell you everything – hairline flaws invisible to the naked eye can cause stainless steel to fail – but it’s a great place to start. Check all terminals and fittings for visual condition and security, paying particular attention to spreader roots and rigging attachment points. At the masthead check the halyard sheaves run smoothly and lubricate them sparingly. Also, check that spreader ends and other items that may damage sails are smooth and well protected with tape.

We’re here to help!

Still feeling a bit stumped quite where to begin, we know time is tight, and fitting everything in around your yacht isn’t always possible. That’s why we provide a range of Yacht Care Services for owners, for those of you with yachts or motorboats moored on River Hamble.

We also provide a variety of ‘one-off’ services ( with no contract required), including wash n go services, storm checks and winter maintenance services to enhance your yacht care.

CONTACT USWHAT CLIENTS SAY

This is truly a 5 * service. The team really looked after us both ashore on arrival and also while at sea. We were a relatively inexperienced crew but always felt the team ashore had our backs. Thoroughly recommended.

I just wanted to say Thank-you very much for the weekend charter. It was exactly what we were after (albeit cold!) plus Andy was an awesome teacher and great company. We’ll definitely be keen to book again soon!

We had a fabulous four days. Marina is ideally placed for the Solent, boat was in great condition, well equipped and a joy to sail. We were well briefed and the shore side team including the dog very friendly.

We charted one of the sailing yachts for a fantastic weekend cruise in the Solent. The boat was in superb condition and well equipped, the staff was very helpful explaining how things work on the yacht and there was also a video available with all the important information. 10/10 would recommend!

Had a fantastic week chartering Blue Otter, Alex was incredibly helpful and sent loads of information and date checking prior to booking. There was a handover video and both the handover and return were really smooth. The boat was lovely and well maintained and Lee was really helpful in recommending places to visit (and helping identify the steering issue as an autopilot takeover - doh!). Definitely will be back and would fully recommend!

Just back from a lovely week in the Solent. Great service from HPYC from first inquiry through to return handover. Very straightforward to deal with, and the yacht was in excellent condition. We've chartered from many companies in the UK and abroad and the attention to detail (and flawless inventory!) was second to none. Everything about the yacht and equipment had clearly been well looked after and was in immaculate condition. Great service, will use again.

Always very friendly service, and well-maintained yachts. Easy check-in and checkout. Will be back...

We had a great time and were very happy with everything. Your team were genuinely friendly and were very helpful when we needed it. Is a big contrast to many charter companies I have dealt with in the past.

Watching the sun go down with a glass of bubbly on the deck of a sparkling yacht was unbelievable. What a treat, and a much needed change of scenery in these troubled times. We will be back for sure

Fab service, nothing too much trouble, including my daft questions. I'll be a repeat customer for sure!

We had a great time sailing with Lee for a few days at the beginning of September. Hamble Point Yacht Charters supplied us an impeccable 45 ft Hanse yacht, which was handled with complete mastery by Captain Lee. It was a privilege to sail with Lee, who is clearly a highly skilled professional taking great pride in his work ... but who is also a fantastic character with a great sense of humour and plenty of fun stories to keep the whole family entertained. He balances the serious side of safety and learning about sailing with a whopping dose of amusement and good cheer. We sailed the Solent in some decent seas, visited Bucklers Hard on the banks of the Beaulieu River and learned lots about British nautical history. Our boys started somewhat of a fishing trend catching bass off the back of the boat in Portsmouth and we would love to sail with Lee again in the future. The man truly knows his stuff, maintained the boat impeccably and went to every effort to ensure that we had a great time. Many thanks to “Shippers” and Hamble Point Charters. We’ll be back.

Chartered bareboats with HPYC on numerous occasions most recently in Sept 2020. Always helpful and accommodating. Highly recommend.

We had a fantastic weekend sailing on Loxley B. Boat in super condition and spotlessly clean, Alex. and the team very thorough and always on hand to answer any questions. A great experience. We will be back. Thank you!

Lots of information from office with a friendly service. We selected a one of the cheaper yachts and was please with find everything work and was cleaned and tidy. We will definitely be back

This was the first time we had tried chartering and as experienced racing sailors we didn't know what to expect. Covid has closed down all our events this year so this was a chance to get afloat at least once in 2020. What a great experience and Alex and all the Hamble staff could not have been more friendly or helpful. We had a great three days and we will be back !! We would have no hesitation is recommending Hamble Point Yacht Charters.